Copy URL to Clipboard

Copy URL to Clipboard

As high tariffs have made trade with certain countries less lucrative than in the past, many businesses have turned to the practice of reshoring in order to avoid these issues. This strategy is one of the most important aspects of bringing manufacturing and product sourcing to the United States.

Key Takeaways

If your business is reeling from tariff turmoil, reshoring should be on your mind. In this article, I’ll go into the subject in detail, including examples of companies reshoring their operations in 2025.

You’ve probably heard the phrase “bring manufacturing back to the USA” or something close to it on the news or social media. That’s essentially what reshoring means: the process of moving away from relying on foreign manufacturers in favor of building or re-opening factories in the U.S.

To provide greater context, here are some other similarly named strategies that contrast with reshoring.

In times of tense international trade relationships, reshoring can be a boon for businesses. As of this writing, several well-known companies are considering or implementing this strategy to avoid prohibitively high tariffs.

Related: Nearshoring Statistics for 2024 Every Business Should Know

One of the most significant examples of a company investing in US production to avoid trade barriers is tech giant Apple. Following the establishment of costly tariffs on Chinese goods, the phone and computer manufacturer committed to spending over $500 billion to build and expand facilities in the United States.

Automakers are following suit. Honda was set to begin producing its popular Civic model in Mexico starting in 2027, but has changed course to build the vehicle in Indiana instead. This move was prompted by uncertainties about the future of the United States-Canada-Mexico Agreement (USMCA), which the current administration has sought to restructure.

Savvy business owners have been quick to question how easy, or even possible, it is to decouple from foreign manufacturing sectors.

In short, yes. The COVID pandemic actually prompted a significant reshoring trend well before the current trade action concerns ever came into being. A study conducted by Medius in late 2023 found that 69% of businesses in the US were in the process of reshoring operations, with nearly 100% describing their efforts as successful.

The real question is this: can manufacturing be brought back to the USA easily?

The impetus for businesses offshoring their manufacturing operations in the first place is easy to understand. In certain countries, laborers can work for a fraction of what it would cost to employ an equally skilled worker stateside. Even after factoring in shipping costs and customs fees, it made financial sense to keep manufacturing operations overseas, particularly in China.

While tariffs and trade restrictions have made it less appealing to source goods from China, there are still significant barriers businesses will face in the process of reshoring. Chief among them are:

With that said, there are good reasons for businesses to endure these difficulties.

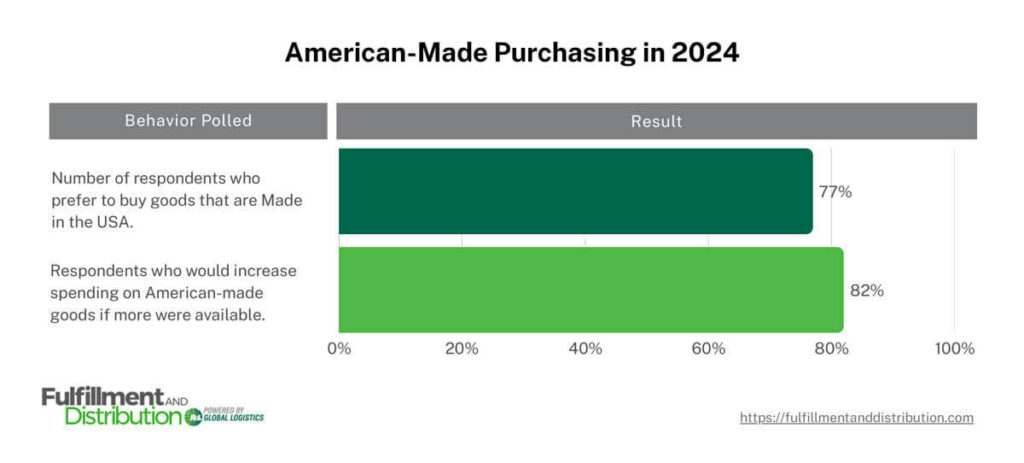

Companies willing to deal with the inherent hardships of reshoring can enjoy a number of benefits. One of the most appealing is being able to stamp your goods as “Made in America.” A poll conducted by the American Alliance for Manufacturing resulted in the following statistics.

Even if reshoring ends up increasing your costs, you may be able to offset them thanks to their perceived superior quality.

Other advantages to nearshoring include:

In short, reshoring is an effective method of simplifying your supply chain while consolidating operations in the United States. With the right assistance, you can take advantage of this strategy to set your business apart from the competition.

If you think your business could benefit from reshoring, we’re here to help. Our experts in the fields of logistics and distribution offer one-on-one consultation services, which can help you create an effective reshoring strategy.

To get started, give us a call at (855) 863-7672 or contact us online. We’re standing by to help you build the perfect distribution strategy for your business.

Copy URL to Clipboard

Copy URL to Clipboard