Copy URL to Clipboard

Copy URL to Clipboard

Putting together the best logistics plan for your business means evaluating several distribution and product storage strategies. Inventory positioning is one such strategy that, when executed thoughtfully, will position your business for profitability and customer satisfaction.

Key Takeaways

In this guide, I’ll explain what inventory positioning entails and the advantages it can offer your business as a shipper in the US.

Schedule a consultation with one of our expert distribution strategists at (855) 863-7672 to start positioning your business for success.

The inventory positioning process involves placing and managing inventory at strategic points in your supply chain with an eye toward balancing costs with lead times and customer service expectations.

This strategy is closely connected to a distribution concept called the push-pull boundary. On a basic level, pushing involves predicting customer demands and meeting/exceeding those expectations based on historical data and projections, where pulling is more responsive to real-time consumer behavior.

For example, standardized goods such as video game consoles make sense to push since they’re largely similar from one model to another. On the other hand, new vehicles require accessorization and options to be added prior to delivery, making them prime candidates for pulling.

Let’s look at some more in-depth examples of inventory positioning at work.

The following scenarios will illustrate push-heavy, pull-heavy, and hybrid inventory positioning strategies.

A retailer of music instruments in a midwestern city is preparing for a demand surge that corresponds with the beginning of a new school year. He uses his own historical sales data to anticipate which instruments are most likely to sell, and moves more stock down the supply chain toward a local distribution center. This lets him replenish his inventory quickly throughout the high-demand period.

The strategy is push-heavy because it:

Now let’s take a look at a situation that calls for pulling inventory further up the supply chain.

A few months later, the manufacturer of the aforementioned retailer’s instruments is getting ready for tax return season. They sell a roughly equal number of different advanced-level stringed instruments with multiple customization options including colors, types of hardware, and electrical components like pickups and tone/volume selectors.

Rather than pushing a variety of instruments close to the consumer, the manufacturer pulls back and prioritizes positioning components at an assembly facility. The instruments are assembled and finished to order, meeting the exacting demands of their customers. Components are restocked using a just-in-time strategy to keep inventory lean and profitable.

This strategy is pull heavy because it:

Now that you’ve seen push and pull inventory positioning at work on their own, let’s look at how they can be combined.

The retailer from our first example has expanded his operation to an ecommerce platform, offering delivery across the country. He has found it lucrative to stage replacement parts and wearable components like drumsticks, strings, and reeds in third-party logistics (3PL) warehouses close to his major customer bases to meet sudden demands for these items.

However, storing expensive, fragile instruments with less reliable demand this far down the supply chain proves to be more of a hindrance than a help. Rather than storing these as finished items, he shifts to a pull strategy that allows his manufacturer to use the same raw materials to make a number of different horns.

We can consider this a hybrid inventory positioning strategy because it:

Determining where in the supply chain to focus your merchandise results in an inventory buffer called a decoupling point. Choosing these points wisely is a key part of smart inventory positioning.

Related: Multi Channel Distribution: Definitions, Strategies, and Examples

While several factors will play into your decision making process, there are five key considerations and tools that almost any business can use along the way, regardless of the products you sell and the size of your customer base.

We’ve already seen this at work in the scenarios listed above: it makes sense to stock finished goods when they sell quickly and predictably. Such goods benefit from a push-heavy strategy, so decoupling further toward the back of the supply chain wouldn’t do you many favors in terms of fulfilling orders in a timely manner.

Conversely, goods that require modification and customization fulfill customer requests make less sense to store in a finished state. Pulling inventory to a decoupling point prior to final assembly makes it easy to respond to unique orders as they come in.

Whether it’s due to natural disasters or political volatility, some raw materials are known to suffer from occasional, unpredictable shortages. Take rare earths for instance, which are often used in international trade negotiations to exert leverage via threats of export controls. When these controls are tightened, raw materials used in the construction of consumer electronics become scarce.

Decoupling inventory at the initial point of refining raw materials would result in a safety stock the manufacturer can draw upon when these situations occur, allowing them to meet demand and wait out the shortage.

Geographical considerations are a major element of inventory positioning and decoupling. For instance, if you intend to distribute goods nationwide, you’ll want to have inventory stocked at multiple warehouses across the country. This will allow you to meet shipping time expectations on both coasts and throughout the US.

Incorporating the various elements of this decision making process into a cohesive strategy is best done with a little help from modern technology. Warehouse management systems (WMS) include software that can analyze historical sales data, demographics, and other factors to help you build a data-driven decoupling strategy that, in turn, boosts your inventory positioning efficiency.

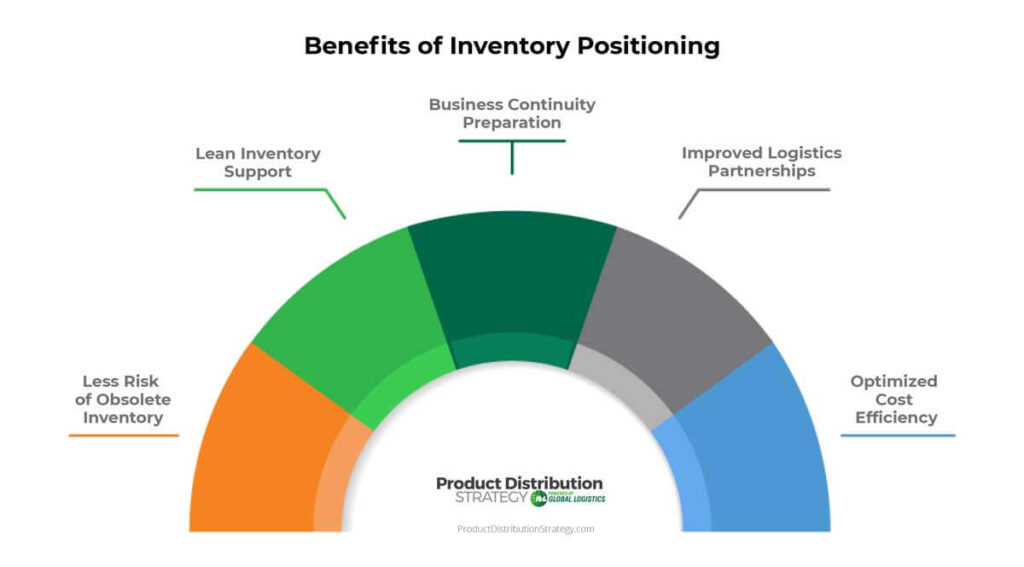

After doing all the hard work of implementing your strategy, you can expect to see some of the following benefits.

The advantages of building out a positioning strategy include:

If you’re looking for assistance building out an inventory positioning strategy, our team of logistics experts can help.

Related: B2B Distribution: Bridging Manufacturers and Retailers

Our warehousing and distribution professionals bring years of experience in this complex industry to the table, helping shippers and shipping companies craft logistics strategies that address their unique business needs. Call us at (855) 863-7672 or fill out a contact form online to find out how we can help you elevate your position.

Copy URL to Clipboard

Copy URL to Clipboard